-

Posts

5,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Posts posted by Koom

-

-

Get under the car and check the knuckle above the steering rack while someone turns the wheel for you.

I don't know if it's possible for the rack itself to shear teeth off??

-

So driving home today while it was wet i took a corner slightly fast and the rear end stepped out like i was on ice...Its been doing it for a while. I usually get understeer entering the corner and once the front grips the rear steps out. Do i just need to stiffen up the rear end or is the front end too loose? Any ideas on what it could be?

Soften the rear end to help prevent it stepping out.

Removing rear swaybar would help prevent it stepping out.

But the **** rear tyres and new front tyre imbalance is the main problem.

-

-

-

Rattle gun is definitely the easiest. A friendly shop should do it for you for nothing if they're not busy - takes 3 seconds. I haven't seen an Allen key slot on factory struts before? You'd need a fricken long Allen key if so - those nuts are tight!

The bilstein's in my gtb had the allen key hex but I had to weld a bar to a deep socket to be able to use it as I don't have those fancy pass through sockets and the nut was too deep for a spanner. Haven't seen that allen key hex on non-bilstein's though.

-

Yeah I joined around 2005 as it was Easter that year when I bought my RS and found Clubsub when trying to find info on fixing it. Still trying to fix it.....haha.

Sad thing is when I think that it's been off the road for probably half the time that I've owned it. And now it's road legal again but I'm incapacitated by a mtb'ing injury so I still can't drive the damn thing!

It was around 2005 that WRXER bought his car off another chch member then later became the local rep. Not sure when he was last on here but he's also still got that same car but now more modified too.

I'm sure that -BLKREX- was around in those days too. But under a different name as I remember him having a white Impreza back then.

-

i split them even running top feeds as i run twin external bosch pumps with there own lines one to each fuel rail then into twin port fuel reg. better to much fuel than to little. safe or sorry take yr pick lol.

That could create the situation where one pump dies and goes lean on two cylinders while the others run fine. Unless you add a leg to balance between the two sides. Or are you relying on the dead side being backfed via the dualport reg?

I wouldn't consider that safe at all personally.

-

no ones mentioned split fuel rails and an aftermarket reg to go with that fuel pump..

that was my first engine mod as we all know subaru's love to lean out.

I reckon thats more of an old sidefeed injector problem and I'm doubtful as to gaining any benefit from splitting the later top feed rails IMO. Same with factory fuel pressure reg. Unless the tuner wants to wind up the base pressure.

-

-

Wait whaaaaat your car moves now?

This is excite

Yeah, all sorted and fully road legal.

Drove it again today. I must say that feels weird to be able to just go downstairs, jump into it and drive it wherever I want. Doesn't seem right, haha.

Also came home and wrote up a page long list of things to do. First is replace the sunvisor that broke off in my hand the other day. Stupid old plastic!

-

Got a cert plate fitted, then finished WOF and paid for some rego. Gave it some fresh fuel and spent the afternoon driving round in it for the first time since ~2009 sometime.

Also introduced the missus to "acceleration" and "boost".....

-

Spent the weekend building an exhaust that is 90% mufflers or resonators and only 10% tubing. Think it might finally be quiet enough to finish the cert and wof process.

Also replaced my modified Toyota rear lateral links with proper Whiteline ones for toe adjustment.

Now just hoping for a good outcome!

-

Yea I've roughly been through the calcs too, get that side of it but aren't dyno's reading torque values rather than power so shouldn't torque always be a reliable figure? Or do they just get a raw figure thats then manipulated by gear ratio's and wheel diameters to allow a power calc to be made and then for some dyno's they show the calculated value rather than the unadjusted one? Just intrigued why some dyno's show huge torque values and others have expected ones whilst still giving relatively consistant power values

So when people say they have Xnm atw is that actually correct saying it that way? Or since you've had to include wheel diameters, gear ratio's and final drive ratio's is that not then considered flywheel values again. Why else would you go to the effort to calculate out any gains created. Torques the turning force at the centre of the axis so shouldn't wheel diameter be the only factor that needs to be considered.

There's obviously different methods of collecting this data that different brands use but say this one measures the turning force the car creates against its rollers. Could that then be the figure they show rather than the torque at the centre axis of the wheels?

Think I might just spend a few days doing a lot more reading.

Can't seem to find any real info for dynotorque dyno's though, don't suppose they go by another name anyone knows of?

There's the metric one

Power (kW) = Torque (N.m) x Speed (RPM) / 9.5488

So then Torque = power x 9.5488 / speed

The dyno is reading the torque at the wheels. Which is multiplied from the crank by the gearbox, diff ratio and wheel diameter.

So you can get a massive torque reading by doing the run in 3rd gear (or 1st...).

The calculation is for estimating torque output of the engine as torque at the wheels is not a useful figure for any sort of comparison.

-

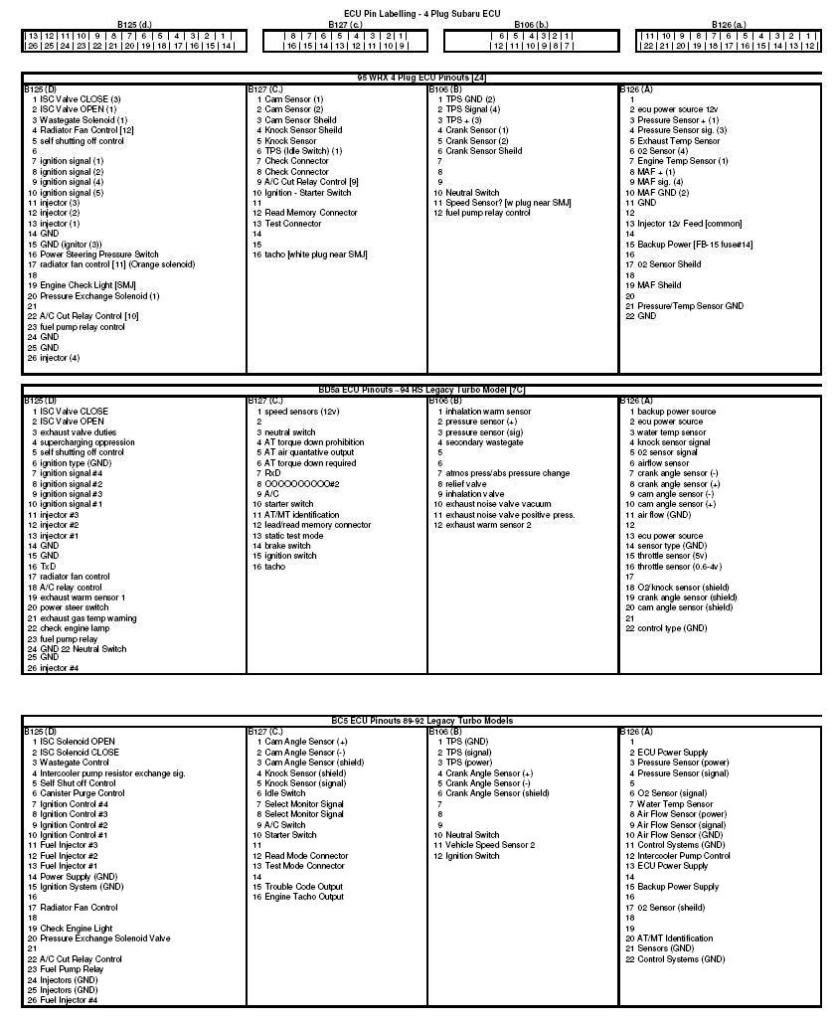

Or a better quality pdf version: https://drive.google.com/file/d/0B3aeMloL3JG-OV9uOFk4eFNJd0U/view?usp=sharing

-

[h=5]HP = Torque x RPM ÷ 5252[/h]

In hp and ft-lbs of torque.

Dyno plots showing torque at the wheels will vary wildly depending on what gear was used, tyre size or hub dyno.

To calculate the correct torque output figure, use the equation above but rearranged to find torque.

Torque = (HP x 5252)/rpm.

So for the max. torque figure, pick the highest point on the torque curve and use the hp and rpm at that point.

e.g. Torque (ft-lbs) = (170hp x 5252)/3500 [bit of guessing around 100 kph]

= 255 ft-lbs (346Nm).

There's metric versions of this calculation but it's too late on a holiday weekend for that sort of carry on.

-

Have you run the tests within the ecu to check for spark on each of the individual cylinders?

Checked the timing with a timing light?

-

Convert to top feed. Can always start with a set of sti pinks and then upgrade to id1000's later if going to a huge turbo. But they're going to better than most side feeds.

-

-

A big Allen key (can't remember the exact size sorry) for that moment when the engine won't come free off the gearbox.

-

how important is lining up the timing belt marks during the timing belt change? Personally I've done it because the instructions said to, but other people are saying it doesn't matter....

If you don't line up the belt with the marks on the pulley's, you've got a very strong chance of bending valves and requiring a rebuild.

-

Just looked at my old notebook and it was a ty755vn5aa and the centre ratio was 40:37 which matches a 4.111 rear to 4.444 front.

It all seems so boring now if the 1.1 came after the centre diff. Mostly a moot point cause I destroyed the clutch pack in it too.

-

I'm going to switch camps on this

(cause its not religion and I've done some more reading)

(cause its not religion and I've done some more reading) After looking at this thread (http://igotasti.com/vBforum/showthread.php/263-DCCD-info-and-FAQs), I never knew that the clutch pack locked up the sun and planet gears so that they couldn't independently rotate. Effectively making it the same as a locked 50:50 diff with no mechanical advantage for either end (rather than just limiting slip between the outputs). So then its back to a locked 50:50 diff can produce 0:100 or 100:0 effective torque at the wheels.

But in steady state i.e. driving along a straight road, it can still only be between 35:65 and 50:50.

I'm still unsold on the 1.1:1 discussion though.

Because there is always a 1.1:1 ratio in the centre of the drivetrain which cannot be locked up 50:50 to give an equal split.

Especially after reading comments by "patr" off Nasioc (i.e. http://forums.nasioc.com/forums/showthread.php?t=1660820)

almost.. except that spider gear sets and reduction ratios in the transfer gear sets actually can control how much torque is applied in the "locked" case or "locked before it slips" case in a viscous or emcd or otherwise plated diff. so yeah we are saying the same thing but your numbers are wrong in some cases. Its really really easy to see on the dyno, for example the 1.1:1 center diff cars vs the 1:1 cars (yes, when wheelspeed is the same, there is differential torque across the front to rear).Still lost on what the rear diff was supposed to be when the gearbox had a 4.444:1 front and 1.1:1 centre. Technically it should be a 4.04:1 rear so with a 4.111:1 rear, there would always be a percentage of slip in the centre diff. Think it was a TY755v1naa? but I forgot to double check that last night.

-

if the wheel is on ice or in the air then it is still receiving 50 % of the torque dumbass

i know exactly how it works .

i do not believe a dccd can make a car ( without axles removed) 100% front wheel drive or 100 % rear wheel drive .

please do educate me on how this is possible

As Optical said earlier, the planetary gear arrangement of the dccd fixes the torque split at 35:65 due to the mechanical advantage. The clutch pack just prevents any difference in speed between either output (if locked, otherwise limits the speed differential or if it's open, allows one end to spin freely but that is still not 100% torque). i.e. you have all four wheels off the ground, you still have to apply a torque to one end to stop them rotating if you want the other to rotate independently so the torque split still applies.

That video also doesn't explain centre diffs that have a set mechanical bias at all. As in a planetary centre diff that in plain, straight ahead driving, will be putting 35% torque through the front axles and 65% through the rear. Then when slip is introduced, the clutch pack works to limit that slip rather than redirect/multiply torque. Clutch packs are just a reactionary part, because the slip comes from one end of the car losing the reaction torque from the ground (ice, mud, lifting the front with weight shift in drag racing.....) So the available torque from the engine is limited but not redirected to the other end of the car.

-

Speed stays the same but the 1.1:1 ratio gives a torque split at the centre cause that is what gear ratios do.

From Power = torque x rpm. Power is the same in both directions, rpm going forward is higher than that going to the rear so the torque has to be lower if that equation is correct.

-

Who's Online 1 Member, 0 Anonymous, 303 Guests (See full list)

What have you done to your car today?

in General Vehicle Discussion

Posted

Drove it. First time I was able to drive in two months, so I chose the biggest pain in the a*! to take out for a fang! Was worth the wait.

Was worth the wait.