Durty-Sanchez

-

Posts

255 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Posts posted by Durty-Sanchez

-

-

Walbro.. PM the GFB guy from the forums, he helped me out with a decent price on one. Cheaper than factory replacement and over 9000 times better..

-

- Whats your intake like? Those flexi-corrigated plastic intake pipes start to tear around the ends... mine had a gash and was leaking badly, took me 4 months and a new set of coils to find the bugger! Sharp jolt sounds AFMish, but a loss like that should store a fault code.

- Coilpacks would be my next bet... they can test them all they want but i'd only ever replace entire sets of 4. If ones bad enough to fail a test then the rest are probably just as old and worn.

- Still have factory BOV?

- TPS as mentioned, although it's still metered air so shouldn't be as jolty as you describe

- Possibly a solenoid in the BBoD, you never really know with that thing

Is it consistently repeatable? Or does it just *happen* sometimes while boosting? If it just *happens* i'd go coils or unmetered air

-

I was thinking more along the lines of the electrical pulses impeadance/resonance differing in the leads at certain frequencies ... again, ideal world, I doubt anyone but a scientist would care so go for it, you can put them pretty much anywhere you want

-

You could mount them in the heads? Oh wai..

Nah it doesn't matter where you mount them.. in an ideal world all the lead lengths would be the same, but it probably doesn't matter a whole lot. Somewhere they don't get too hot would be a bonus

-

Magnetic for me (280,000+ kms)... the older TT's like yours are a bit more robust than the newer ones

-

If I were you and wanted something decent I'd run the exhaust from the secondary down just clear of the firewall. Your car will sound stock on the primary, but as soon as you hit secondary it'd go nuts. Not to mention your VOD would disappear dramatically. Put a flange on the end of the pipe and the Y-join too so you can replace it with a pipe at WOF time, while at other times it vents and you just use a blocking plate over the Y-join flange.

Much more fun than going single, which as RH says is a bugger to do with your version...

-

Looking to verify this... on a TT legacy (BD) the oxygen sensor is the bugger in the primary downpipe (post turbo), not the joker in the headers (pre turbo).. sound about right?

-

I think that the primary WG is more than enough, given the bulk of the flow is through both turbos. The secondary WG has no PWM control so there's little in the way of adjustable boost control from factory. The only possible time that the secondary is used would be when the boost level in the secondary outlet pipe exceedes the secondary WG spring pressure (no idea what that is) and it opens to keep stuff from blowing up. Here's how you can test it.. disconnect the secondary WG then go give it a thrash. If your boost goes crazy then it turns out that you did need it afterall, otherwise you should be fine.

Yea providing MAP to the secondary WG would open it, which would of course bleed exhaust energy from the system and slow down secondary spool times.. I think the secondary WG lies after the main exhaust actuator valve so opening this during primary operation wont do squat, it'll only factor in once the main valve is open. I'd leave it shut, it's kind of redundant in the setup - probably why it was lost in later versions.

From what I've seen the boost is controlled entirely by the BCS, which is in turn connected to the primary WG. At no point is the secondary WG ever used. During secondary spool up all exhaust gas vents through the turbine, and then once fully online boost continues to be controlled using the primary WG. During secondary operation the primary WG has less exhaust gas to pass through it, as the majority of the gas is already being expelled through both turbines, so if anything it becomes more effective

/quote]

So with your experience the primary WG is enough full stop, which is good in my eyes (less to control). I just want to understand their exact concept behind why it was 'thought' to be needed in the first place... It's really bugging me!

I will still operate WG#2 manually now and then I think, just so it doesn't cease up. With the way I have done the install it's completely reversible by unplugging the OEM ECU, and plugging in the Link G4 Xtreme and putting in place one fusible link to power up the supply relays. I have done this so I can pull it in and out at will and operate on one or the other easily. If the OEM uses the second WG, I can't have it ceasing on me

-

#22 feeds one side of the differential pressure sensor, which lets the ECU know when to open ICV.

#16 feeds from the same place, and if memory serves me right it acts as a pressure source either for the secondary wastegate or something else. The secondary wastegate isn't used on early models, so the line is fairly redundant. He blocked one side to keep the DPS happy, and possibly the other just to seal it all up. If I can find my TT diagram somewhere I could tell you for certain!

-

the dunlop MY01 is fine for a daily - low road noise and wears well.. and its not ugly..

and ok on the wallet..

+1 .. MY01's aren't the worst tyre in the world and are infinitely better than Federals. If getting a full set you can usually get them down pretty cheap. I think I paid about $140 per corner last time when I agreed to a $60 wheel alignment. Crying poor around xmas time also helped! Play the tyre co's off against each other for price to get the best deal.

-

Yea providing MAP to the secondary WG would open it, which would of course bleed exhaust energy from the system and slow down secondary spool times.. I think the secondary WG lies after the main exhaust actuator valve so opening this during primary operation wont do squat, it'll only factor in once the main valve is open. I'd leave it shut, it's kind of redundant in the setup - probably why it was lost in later versions.

From what I've seen the boost is controlled entirely by the BCS, which is in turn connected to the primary WG. At no point is the secondary WG ever used. During secondary spool up all exhaust gas vents through the turbine, and then once fully online boost continues to be controlled using the primary WG. During secondary operation the primary WG has less exhaust gas to pass through it, as the majority of the gas is already being expelled through both turbines, so if anything it becomes more effective

-

First question: Only subaru knows.. I suspect that as it was their first crack at a TT it was a precautionary thing more than anything (or that's just how IHI make the damn things). The secondary WG is not PWM controlled so it's a straight on/off sort of control. I can't find any mention of it in the firmware, although I haven't spent long looking.

Second question: I am fairly sure (this has been a few years now) that the solenoid that controls the secondary bypass valve switches vac or atmospheric on when it needs to be held open. It's essentially a standard BOV that triggers when the feed (provided via solenoid) has lower pressure than the input (from the secondary turbo). So.. you have a way for the secondary turbo outlet pipe to spool, and any pressure spill-over is fed back in to the intake duct rather than being allowed to build and put pressure on the turbine (because the i/c valve is still closed). The BOV's trigger feed can either be connected to Vac or even atmospheric, as both will allow pressurised air from the spooling turbo to vent back to the intake. Once the secondary has spooled sufficiently this trigger hose is fed with positive pressure to make sure it stays shut and keeps the TT system a happy place.

Of course if i've just c0cked this up and the BOV is pointed the other way then only vac on the trigger feed line will open it - provided it's at a lower pressure than the intake duct.

Anyway, might steer you in the right direction..

-

Anyone heading from Hamilton to Welly (or Masterton) anytime in the next 2 weeks? 4x 17" wheels, happy to contribute to gas

-

Did you drop it? Fragile little things.. either that or it's not plugged in properly?

-

Knock sensor can go if it overheats, especially given their age. I'd replace it though, so long as the ECU is packing a sad over it, it'll be retarding the timing and robbing you of fueleconomy/fun. $140 is a steal though, I was quoted $164 new from Subaru!

-

Could be water pump, sounds a crap load like what happened to me. Split hoses caused the coolant to boil, I fixed the hoses but corrosion had set in. Driving along and the temp would go through the roof and push water out through the overflow bottle. Passed the TK test just fine (detects hydrocarbons in the water), pressure test didn't cause any water to end up in the cylinders so it was unlikely the headgasket. Suspected blocked radiator so was flushed and pipe cleaned.. no difference. Suspected blocked heater core so was flushed, no difference. The damn thing just wouldn't hold water! Suspected busted thermostat so was replaced.. no difference. Looked at water pump and found this:

If they can get in there with a little mirror (like the dentists use) and inspect the fins that'll save pulling it off.. if it's f**ked like mine that'll be what the problem is. Those badboys are bent too, I suspect a massive wad of limescale/corrosion went through it after it had boiled and I was reving the tits off it.

edit: to shrink unruly picture

-

+1, Replace the thermostat

If the top hose is hot but bottom one is cold it means there is no flow in the cooling system, thus cuasing the overheating as the hot water is staying in the block and not traveling around

IF replacing the thermostat doesn't fix the issue then it might pay to look at the waterpump

This

-

is SSM or OBDII TTL levels? Cant seem to figure it out

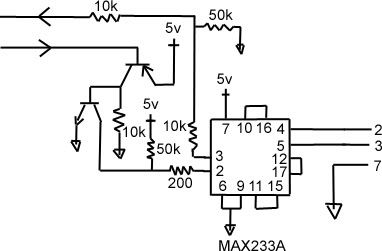

SSM is TTL.. here's the first setup that I used (before switching to USB). All that you'd need to do is remove the max232 chip and replace it with the AVR. This setup hooked in to the com port on a PC. I've just assumed a 5v source in the diagram, on the actual board I took 12v from the diagnostics plug and regulated it down to 5v.

OBD2 - specifically that used in Jap cars is 12v High 0v Low logic:

ISO 9141-2 (Asynchronous serial communication at 10.4 Kbaud)

Pin 7: K-line bidirectional for communication

Pin 15: L-line (optional) unidirectional for waking up the ECU

Idle signal levels are high

Signals are active pull-down to 0V (0.00 to 2.40)

High signal voltage level: +12V (min/max 9.60 to 13.5)

Up to 12 message bytes, excluding frame delimiters

Bit Timing;

UART signaling at 10.4K baud, 8 data bits, no parity, 1 stop

By the looks of the ELM datasheet, the chip is just a PIC micro in disguise.. you need to add most of the external circuitry (to get it to 12v for the OBD and RS232 voltages) yourself..

-

SSM works to way back in the early 90's.. I ripped my ROM out (94 legacy) using it. Just left a laptop in the car overnight with my max232 board and some shady app I wrote. SSM will give you access to every memory location available to the cars MCU, where as OBD2 is limited to RAM locations for sensors.. depends what you're trying to get I suppose! Helps to use some amplification on the ECU -> PC lines as the ECU struggles to drive the lines. Pull-ups help, but I often use a bastardised sziklai pair for the amp stage

-

I'm not 100% sure on OBDII as I only access the ECU using the SSM protocol (Subaru select monitor) .. to access the SSM you need your standard Tx/Rx lines at 5v TTL level (pins 12 & 13 respectively), and you can use the 12v power line to power the whole circuit. SSM is cooler, you can get more stuff and is the native subaru ECU protocol.

From memory OBDII uses half-duplex serial communication over the K-line (i.e. you send a request packet and then listen in on the line for the response) so you'll need to handle this in software or something. The K-line idles high and you can potentially tie Rx and Tx together in the circuit, so long as you use software to ignore the packets that you essentially send to yourself. Packets are 12bytes max (including crc) so you can easily write a routine to manage the half duplex comms.

Try googling 'SSM' or 'Subaru select monitor' .. it'll be more fun

-

If you're using an AVR (or other micro) you wont need the max232.. the AVR's built in 5v logic is what the ECU uses, you'd only need the Max232 if you wanted to USART with a PC. So just jack up the AVR's USART lines with the ECU ports and you're away (I forget the frame settings though.. 1 stop bit no parity from memory). One thing to look out for is the unusual baud rate.. you'll need to select your AVR clock and prescaler properly to reduce transmission errors

-

I wasn't actually enquiring, just curious

All good.. your car *is* tunable, it just needs some extra circuitry added. That'd allow you full blown access to the entire firmware code, inc. parameter tables, the works. As the milder alternative you can chip it, which will sort out the retardation of the timing at low rpm's (and beef it up at higher rpm).. it'll also do the cuts and a few other tweaks. Drop me a line if you ever get around to it

-

You're in luck.. I can do your car. To the PM mobile!

-

I think they were trying to have me on then, this is the relpy I got whwn I asked about getting 4:

Prices and availability below.

Coil packs: 22433aa421/22433aa390 x 4 both supersede to same part number $195.00 + gst each, stock ex CH-CH branch only.

Note the coils are ex CH-CH branch and the only stock in the country. If you need be quick or the new price 15 days ex Japan is $321.00 + gst each .

Would have taken 4 if they were $115 each

Hmm.. mine were single bolt 22433AA330's x4 from Subaru parts (Chch) .. 110 + gst each after a whinge. Not sure if yours are different part/more expensive, but i'd say they're taking you up the arse with those prices. If you don't have any luck with the various parts departments (don't waste your time with Welly - they suck) or anyone who can do hookups, definitely consider the bosch/non-coil-on-plug option.

Edit: speeling

-

Who's Online 0 Members, 0 Anonymous, 181 Guests (See full list)

- There are no registered users currently online

94 Legacy GT running rough/low boost

in Legacy & Outback

Posted

Chipped and cracked coils? My money's on the coils being the culprit here... if you like I have a full set that are 4 years old. I've already set them aside for someone else, but you're more than welcome to try them out to see if it improves your problem. If it doesn't then at least you know you dont need to fork out for new coils!

I'm in welly, PM me if you're keen.

Fuel pump's another one worth considering (if you haven't done it already). Could be running out of steam at this age, which is a very common problem. Knock sensor going stupid will pull the timing and put the ECU in to safe-mode. Does the knock sensor CE code come up? If you like I can have a listen to the knock sensor to see if it's poked or not if/when you try the coils.