Optical

-

Posts

1,129 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Store

Posts posted by Optical

-

-

Qwerty made 245kwatw on the TP dyno with a vf34 and some a/m top mount.

Needed 10% methanol to get there though. It had a surge problem at mid rpm, but AVCS would fix that

-

Got my BD5 in 2005 and the type R in 2006, so going 11 years on CS for me

-

I flooded my old gt28 with no restrictor and fed with a -4AN line. A 1mm restrictor sorted it.

Edit - that exact aluminium plug in thingy in the Speedflow link

-

I dont have anything particularly constructive to add other than I stripped a v7 engine once that had white and partially melted exhaust valves from running very lean due to a valve seat leak. Best to do a leakdown test or similar if you suspect they could have been bent

-

Ive done the twin td04 thing and they are too small a combo for a 2.5, look at VF turbos with a p18 housing minimum for a TT setup.

-

Did you change your manifold? VE will change a bit so AFR changes are normal

Solenoid is closed when not energised and controlled by PWM

-

My clearances are small but I've measured them with the heads off

and I'm wondering if the clearances will increase when the head in

torqued down to the block?

I have only measured one side so far, but I've got .005" to .006"

for the intake and .007" to .008" for the exhaust. Standard is supposedly

.008" for the intake and .010" for the exhaust. I read somewhere the

clearances could be reduced by by .001 to .0015 for an aluminium block

and head... also that smaller clearances was a trick to have bigger looking

cams.

Thoughts?

Mine changed a little when i torqued down my last head, the deck isnt perfectly flat (but still in spec) anymore though which may have contributed. Depending on what buckets you have it's not too big a deal to sort out clearances once the heads are torqued up

-

You're in luck - you can buy the stickers you want separately and still run good gaskets

-

This one isnt boxed but the legs come off.. I've borrowed a few wagons to move it in the past but not an impreza...

Bootlid closed and everythin? ok, i will set out to pick it up with optimism

-

-

Once you fabricate a setup to fit the gt35r and find it to be too laggy, it's easy enough to switch to a smaller t3 flanged turbo that will be great...

I can sell you a real gt35r 63 that's in good condition for a reasonable price.

-

Yeah ive got 4 doors but I don't like em as much , I've wide bodied mine and I won't be bending too many I just need some to start with , I've started off with nothing but bare shell . I can make some fibreglass ones but I just want some factory ones to make mould

I'll lone you a set if you one if you make me FG doors?

-

i havent got my bits back from a friend who borrowed them.. over a year ago

that log was messing about on the motorway iirc, i should fins a log from the track, wasnt that laggy but the 63 is def much quicker to get going...

-

my 82 housing was around 1:1

-

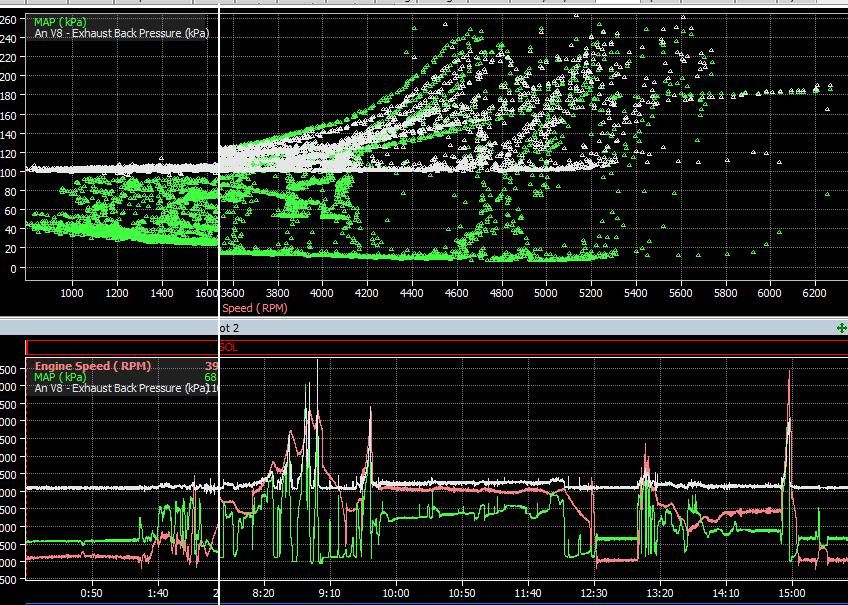

I drilled a hole through a spare sump plug and brazed about 30cm of brake line to it. At the end of the brake line a vac line attaches and leads to a spare MAP sensor for logging

-

Yep on e85 it's bloody ridiculous, I'm now redesigning it all, to try and improve it. At Manfield I was doing 5 laps then having to slow down as it was filling and going into the intake.

You will definitely need a recirculating breather setup for track work. Dual containment areas seems to work pretty well for most of us

-

Ive been looking at building a motion simulator for the driving sims, seems not too difficult.

After driving on a monster sim in Abu Dahbi I was very impressed and really want one haha

This forum has lots of good info on it http://www.xsimulator.net/community/forums/diy-motion-simulator-projects.22/

-

I hate my whiteline ones... Non OEM bolt head sizes (16mm or something) and they slip too often

Are there alternatives?

Next time I have the struts out I'm going to slot the clevis holes and go back to OEM bolts

-

The dccdpro g sensor is 2-axis which means it cant tell the difference between lateral G force, road camber and bumps. Also the response is not really tuneable. To make the thing work properly is a perilous exercise. Good marketing on his part but it's smoke and mirrors.

MapDCCD has a 3-axis accelerometer, it can distinguish lateral g from everything else happening to the car, doesnt need to be mounted flat and of course the response can be tuned so you can mount it wherever you like. We also do a dash cluster driver...

-

Qwerty used these things to fit phase 2 injectors http://www.carldavey.co.uk/product.php?id=2

Could do that and fit decap v5/6 yellows..

Alternatively I need to change intake manifolds soon probably to a top feed injector type one so my Sard 800s and rails will be surplus. Wont be for a month or two though.

-

Just leading a sheltered life lol

-

Ah didnt know

never looked at a non-dccd box!

never looked at a non-dccd box! -

The static torque split is made by a planetary gear system - this works independently of speed and diff ratio and also allows the dynamic torque split to vary depending on f/r wheel traction. The centre diff operates to mitigate the dynamic torque split.

-

-

Who's Online 0 Members, 0 Anonymous, 222 Guests (See full list)

- There are no registered users currently online

EJ20G running like ****e

in Engine Related

Posted

Hey all

Im trying to trouble shoot an EJ20G setup in my v2 wrx ****box runabout

Current behaviour is it severely lacks torque. From the sound of the engine and turbo behaviour it appears the ECU is pulling all the timing out of the engine. Revs slowly, makes lots of wooshing and hissing noises but goes nowhere.

Engine will also not rev past 4000rpm

Typical limp mode behaviour?

Funny thing is, it will behave like this straight after an ECU reset. I'd expect things to work properly if no fault code is bought up.

Maybe the cam belt has jumped a tooth or something? Although I didnt think this would cause a 4000rpm limiter of sorts.

Any ideas?